How Temperature Variations Impact Equipment Performance

- Aug 8, 2025

- 3 min read

Temperature variations are a critical factor affecting the performance and reliability of equipment across many industries. From automotive systems to aerospace components, fluctuations in temperature can cause significant changes in material properties, mechanical behavior, and electronic functionality. Understanding these impacts is essential for engineers and technicians tasked with maintaining and improving equipment durability and efficiency.

Understanding Temperature Variations and Their Effects

Temperature variations refer to the changes in temperature that equipment experiences during operation or storage. These changes can be gradual or sudden, and both types can influence equipment differently. For example, a slow increase in temperature might cause materials to expand steadily, while a rapid temperature spike could induce thermal shock, leading to cracks or failures.

In automotive applications, engine components such as pistons and cylinders expand and contract with temperature changes. If these variations are not accounted for, it can lead to increased wear or even catastrophic failure. Similarly, in consumer electronics, temperature fluctuations can affect battery life and circuit board integrity.

Materials respond to temperature changes by expanding or contracting, which can cause mechanical stress. Metals, plastics, and composites all have different coefficients of thermal expansion, meaning they react differently to the same temperature change. This mismatch can cause joints or seals to fail, leading to leaks or mechanical breakdowns.

The Role of Temperature Variations in Equipment Reliability

Temperature variations are a major contributor to equipment degradation over time. Repeated heating and cooling cycles can cause fatigue in materials, leading to cracks and eventual failure. This phenomenon is known as thermal cycling fatigue and is especially critical in aerospace and military equipment where safety and reliability are paramount.

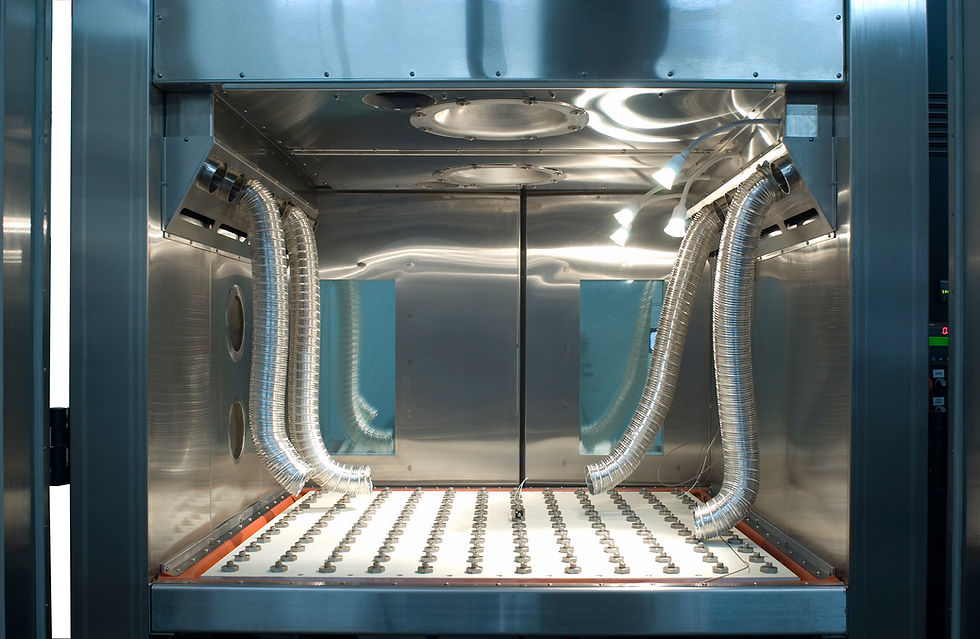

In test laboratories, equipment is often subjected to controlled temperature variations to simulate real-world conditions. This helps identify potential weaknesses and improve design robustness. For example, electronic devices are tested under extreme temperature ranges to ensure they function correctly in both hot and cold environments.

To mitigate the effects of temperature variations, engineers use several strategies:

Material selection: Choosing materials with compatible thermal expansion coefficients.

Thermal insulation: Using insulating materials to reduce temperature fluctuations.

Design adjustments: Incorporating expansion joints or flexible components.

Active cooling or heating: Implementing systems to maintain stable operating temperatures.

These approaches help extend equipment life and reduce maintenance costs.

What is the rate of temperature change in the US?

The rate of temperature change in the US varies significantly depending on geographic location and season. In some regions, temperatures can shift rapidly within hours, while in others, changes are more gradual. This variability poses challenges for equipment designed to operate nationwide or in multiple climates.

For example, equipment used in northern states may experience rapid temperature drops during winter nights, causing contraction stresses. Conversely, southern states might see rapid heating during the day, leading to expansion stresses. Understanding these regional differences is crucial for designing equipment that can withstand local environmental conditions.

In industries like aerospace and military, where equipment may be deployed globally, accounting for the rate of temperature change is vital. Rapid temperature shifts can cause condensation, corrosion, and material fatigue, all of which compromise performance and safety.

Practical Recommendations for Managing Temperature Effects

To ensure optimal equipment performance despite temperature variations, consider the following practical recommendations:

Monitor environmental conditions: Use sensors to track temperature changes in real-time.

Implement predictive maintenance: Analyze temperature data to predict when equipment might fail.

Use temperature-resistant materials: Select materials designed to withstand expected temperature ranges.

Design for thermal expansion: Include features that accommodate material expansion and contraction.

Control operating environment: Where possible, maintain stable temperatures using HVAC or cooling systems.

Regular inspections: Check for signs of thermal fatigue, such as cracks or warping.

Training and awareness: Educate technicians on the impacts of temperature variations and proper handling procedures.

By applying these strategies, reliability engineers and technicians can reduce downtime, extend equipment lifespan, and improve safety.

Future Trends in Temperature Management for Equipment

Advancements in materials science and sensor technology are shaping the future of temperature management in equipment. Smart materials that adapt to temperature changes and self-healing composites are being developed to enhance durability. Additionally, IoT-enabled sensors provide continuous monitoring, allowing for more precise control and predictive maintenance.

Artificial intelligence and machine learning algorithms analyze temperature data to optimize equipment operation and maintenance schedules. This proactive approach minimizes the risk of failure due to temperature variations and improves overall system reliability.

As industries continue to demand higher performance and longer equipment life, understanding and managing temperature variations will remain a top priority.

By recognizing the critical role temperature variations play in equipment performance, engineers and technicians can implement effective solutions to mitigate risks. This knowledge ensures that equipment operates reliably across diverse environments, ultimately supporting safer and more efficient industrial operations.