Mastering Environmental Stress Testing for Reliable Products

- Sep 10, 2025

- 4 min read

In today’s competitive markets, ensuring product reliability is not just a goal but a necessity. Products in automotive, aerospace, consumer electronics, and military sectors face harsh conditions during their lifecycle. To guarantee performance and durability, manufacturers must rigorously test their products under simulated real-world stresses. This is where mastering stress testing methods becomes crucial. By applying these methods effectively, companies can identify potential failures early, improve designs, and meet stringent industry standards.

Understanding Key Stress Testing Methods

Stress testing methods encompass a variety of techniques designed to push products beyond their normal operating limits. These methods help reveal weaknesses that might not be apparent during standard testing. Some of the most common stress testing methods include:

Thermal Cycling: Alternating between high and low temperatures to simulate extreme environmental changes.

Vibration Testing: Applying mechanical vibrations to mimic transportation or operational conditions.

Humidity Testing: Exposing products to high moisture levels to assess corrosion resistance and electrical integrity.

Shock Testing: Subjecting products to sudden impacts or drops to evaluate mechanical robustness.

Altitude Testing: Simulating high-altitude conditions to check performance under low pressure.

Each method targets specific failure modes. For example, thermal cycling can cause solder joint fatigue in electronics, while vibration testing can reveal loose components or structural weaknesses. Selecting the right combination of stress testing methods depends on the product’s intended use and the environments it will encounter.

What is Environmental Stress Screening?

Environmental Stress Screening (ESS) is a specialized form of stress testing that focuses on exposing products to environmental extremes to detect latent defects. ESS typically involves cycling products through temperature, vibration, and sometimes humidity stresses. The goal is to precipitate failures that might occur in the field but remain hidden during normal testing.

ESS is widely used in aerospace and military applications where reliability is critical. By forcing early failures, ESS helps manufacturers identify design or manufacturing flaws before products reach customers. This proactive approach reduces warranty costs and enhances product reputation.

The process usually follows these steps:

Pre-screening Inspection: Visual and functional checks before stress application.

Stress Application: Cycling through temperature and vibration profiles based on product specifications.

Post-screening Inspection: Identifying any failures or performance degradation.

Failure Analysis: Investigating root causes to implement corrective actions.

Implementing ESS requires precise control of test parameters and thorough documentation. It is essential to tailor the screening profiles to the product’s operational environment to avoid over-stressing or under-testing.

Practical Tips for Effective Stress Testing

To maximize the benefits of stress testing methods, consider the following practical recommendations:

Define Clear Objectives: Understand what failure modes you want to detect. This guides the selection of stress types and levels.

Use Realistic Profiles: Base test conditions on actual field data or industry standards to ensure relevance.

Monitor Continuously: Use sensors and data acquisition systems to track product behavior during tests.

Document Thoroughly: Keep detailed records of test conditions, results, and any anomalies.

Iterate and Improve: Use test outcomes to refine product design and manufacturing processes.

For example, in automotive electronics, thermal cycling combined with vibration testing can uncover solder joint cracks caused by temperature expansion and mechanical stress. By identifying these issues early, engineers can modify materials or assembly techniques to enhance durability.

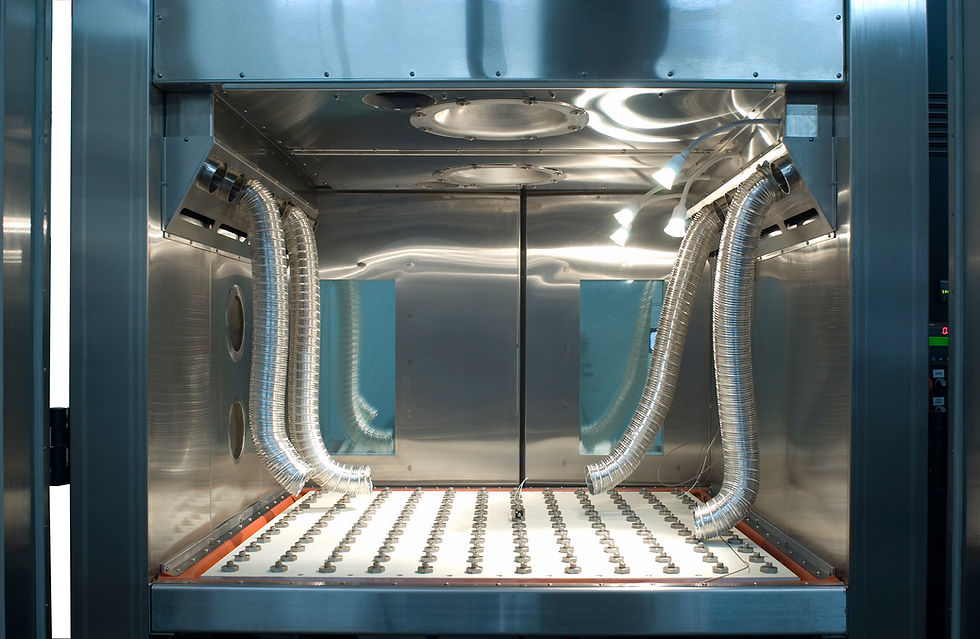

Additionally, integrating automated test systems can improve repeatability and reduce human error. Modern environmental chambers and vibration systems offer programmable profiles and remote monitoring, making testing more efficient.

Leveraging Advanced Testing Equipment

Choosing the right equipment is vital for successful stress testing. Advanced environmental testing chambers and vibration systems provide precise control over test parameters. Features to look for include:

Wide Temperature Range: To simulate extreme hot and cold conditions.

Humidity Control: For testing moisture-sensitive products.

Programmable Profiles: Allowing complex cycling and combined stresses.

Data Logging: Capturing real-time test data for analysis.

Safety Features: Protecting both the product and operators.

Companies like Hanse Environmental specialize in providing such equipment tailored to various industries. Their solutions help accelerate development cycles by enabling thorough and repeatable testing.

When selecting equipment, consider the product size, test duration, unit throughput, and required environmental conditions. Investing in high-quality systems pays off by reducing product failures and speeding up time to market.

Moving Forward with Confidence

Mastering stress testing methods is a strategic advantage for any manufacturer aiming to deliver reliable products. By understanding the nuances of different testing techniques and applying them thoughtfully, you can uncover hidden defects and improve product robustness.

Remember, environmental stress testing is not just about pushing products to their limits but about gaining insights that drive better design and manufacturing decisions. With the right approach and equipment, you can confidently meet industry standards and exceed customer expectations.

Embrace these practices to build products that stand the test of time and environment. Your commitment to rigorous testing today will translate into fewer failures, enhanced reputation, and greater success tomorrow.