Unlocking Robust Reliability: Step-by-Step Guide to Implementing HALT and HASS

- Oct 10, 2025

- 2 min read

Transforming Product Quality with Proven Accelerated Testing Strategies

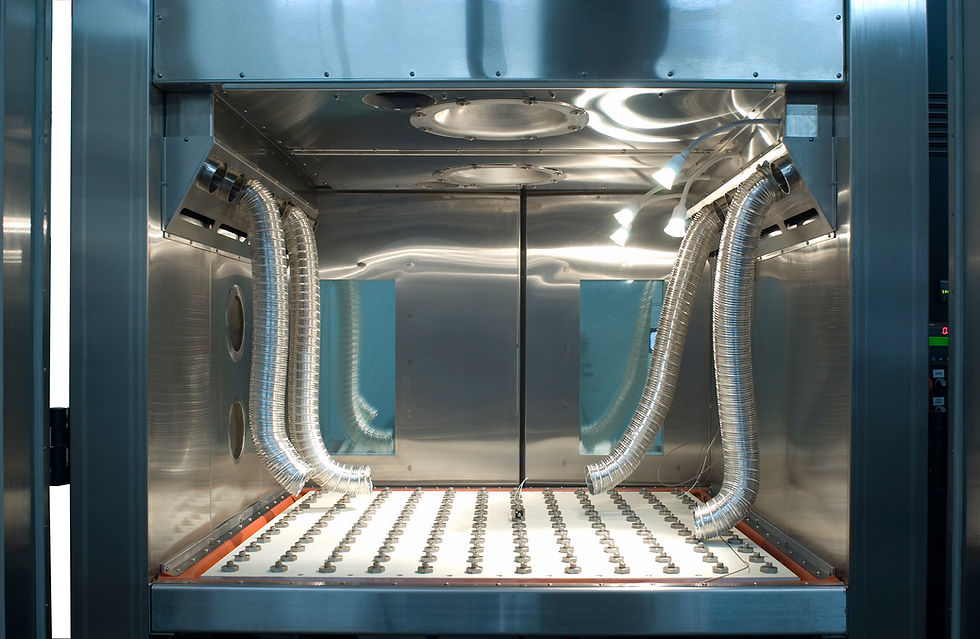

Implementing HALT (Highly Accelerated Life Testing) and HASS (Highly Accelerated Stress Screening) in a company’s quality and reliability department involves a structured process from design validation to ongoing production screening. Below are the key steps, best practices, and pitfalls to avoid when integrating these powerful reliability tools.

Introduction

In today's competitive market, ensuring product robustness and high reliability is non-negotiable. HALT and HASS are proactive quality methodologies that push designs and manufacturing processes beyond standard conditions to reveal hidden weaknesses and eliminate early-life failures before they reach customers. Implementing these in a company's quality and reliability department requires careful planning, resource allocation, and a commitment to ongoing improvement.

Step 1: Secure Stakeholder Buy-In

Top management support is crucial for cultural and resource alignment during HALT/HASS rollout.

Share the business value: fewer warranty claims, higher customer satisfaction, and lower lifecycle costs.

Step 2: Establish a Cross-Functional Team

Form a team including design, test, manufacturing, and quality professionals for broad expertise.

Assign HALT/HASS ownership for accountability and knowledge retention.

Step 3: Select Pilot Products

Start with new or critical products where reliability is paramount, or problematic legacy designs with recurring field failures.

Step 4: Define Test Specifications and Success Criteria

For HALT: Identify operational and destruct limits for temperature, vibration, power cycling, and other relevant stresses.

For HASS: Derive production screening stress levels based on HALT findings, always remaining within safe guard bands for product life.

Step 5: Conduct HALT

Use thermal and vibration step-stress to drive failures and uncover design weaknesses.

Analyze each failure thoroughly and implement improvements; repeat as needed until diminishing returns or cost-effectiveness is reached.

Avoid pass/fail mentality—focus on learning from every failure.

Step 6: Establish the HASS Process

Design HASS screens to uncover latent manufacturing defects by applying simultaneous, accelerated stresses (typically less severe than HALT, but derived from its data).

Customize every HASS profile for each product and update them after significant design or process changes.

Consider both precipitation (to expose hidden flaws) and detection (to identify those flaws) stages.

Step 7: Integrate with Production

Implement HASS as a routine screen in manufacturing, either on all units or a statistically significant sample.

Capture, document, and analyze failures, feeding improvements back to the design team or process engineering.

Step 8: Continuous Improvement

Regularly review HALT and HASS results alongside field reliability data.

Update test protocols and corrective actions as new failure modes or process changes arise.

Best Practices and Pitfalls

Start HALT early in the product lifecycle for maximum impact.

Avoid generic tests; always customize screens to the product.

Maintain a data-driven feedback loop between testing, design, and production teams.

Never implement HASS without first defining robust limits through exhaustive HALT.

Document every corrective action and verification step in a shared database for traceability.

Takeaway

Integrating HALT and HASS transforms a quality and reliability department into a proactive defender against product failures. By following these steps, companies can uncover and resolve weaknesses before products reach the field, ensuring robust performance, delighted customers, and industry-leading reliability.