Benefits of HALT HASS Testing Chambers

- Dec 20, 2025

- 4 min read

In the fast-paced world of product development, ensuring reliability and durability is paramount. Products must withstand harsh environments and rigorous use before reaching customers. This is where environmental stress screening techniques like HALT (Highly Accelerated Life Testing) and HASS (Highly Accelerated Stress Screening) come into play. These methods help identify design weaknesses early and improve product robustness. Today, I want to share insights into the benefits of HALT HASS testing chambers and how they can transform your testing processes.

Understanding Halt Testing Advantages

HALT testing is a proactive approach designed to push products beyond their specified limits. By exposing devices to extreme temperature and vibration conditions, HALT reveals potential failure modes that might not appear during standard testing. This accelerated testing helps engineers identify weak points in design and manufacturing processes quickly.

Some key advantages of HALT testing include:

Early Detection of Design Flaws: HALT stresses products to failure, uncovering hidden weaknesses before mass production.

Reduced Development Time: By identifying issues early, teams can iterate designs faster, shortening time to market.

Improved Product Reliability: Products that survive HALT are more robust and less likely to fail in the field.

Cost Savings: Catching failures early reduces warranty claims and costly recalls.

Enhanced Customer Satisfaction: Reliable products build brand trust and reduce service costs.

For example, in the automotive industry, HALT testing can simulate extreme temperature swings and road vibrations that a vehicle component might experience. This ensures parts like sensors or control modules perform reliably under real-world conditions.

What is the difference between HASS and HALT?

While HALT focuses on pushing a product to its limits to find design weaknesses, HASS is a production-level screening process. HASS applies stresses identified during HALT to every unit manufactured, ensuring consistent quality and catching manufacturing defects.

Here’s a breakdown of the differences:

| Aspect | HALT | HASS |

|----------------------|--------------------------------------|--------------------------------------|

| Purpose | Design validation and improvement | Production screening and quality control |

| Stress Levels | Higher than product specifications | At or slightly above product specifications |

| Frequency | Performed during development phase | Performed on every production unit |

| Outcome | Identifies design weaknesses | Detects manufacturing defects |

For instance, aerospace components undergo HALT during design to ensure they can handle extreme conditions like rapid temperature changes and vibration. Once the design is validated, HASS is used on the production line to screen each part for defects introduced during manufacturing.

Understanding these differences helps optimize testing strategies and ensures products meet stringent reliability standards.

Practical Benefits of Using a halt hass chamber

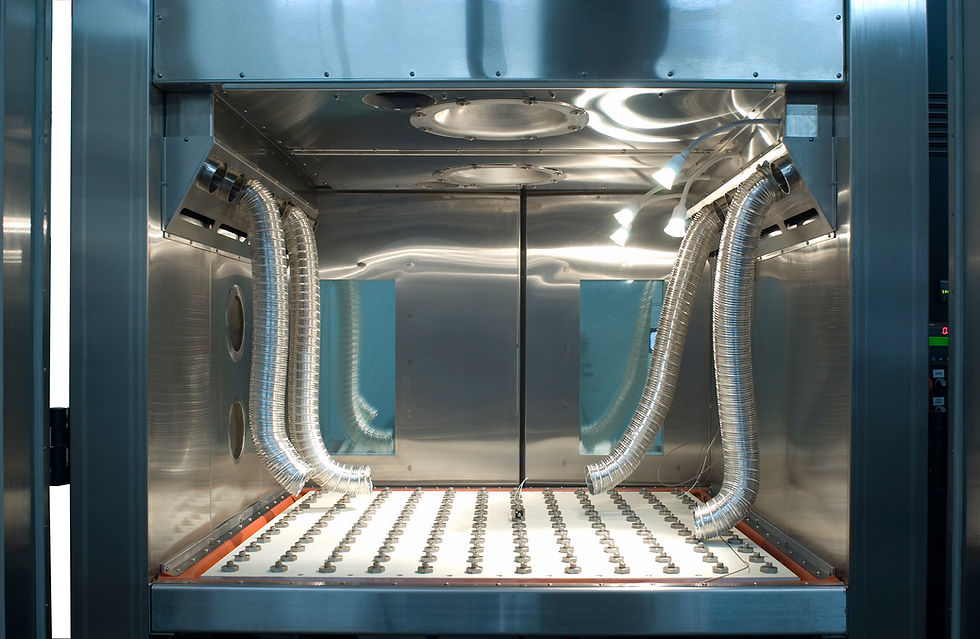

A halt hass chamber integrates temperature cycling and vibration testing in a single system. This combination accelerates the identification of failure modes and streamlines testing workflows.

Here are some practical benefits of using such chambers:

Space and Cost Efficiency: Combining thermal and vibration testing reduces the need for multiple separate chambers.

Faster Testing Cycles: Simultaneous stress application shortens test duration.

Improved Test Accuracy: Integrated control systems ensure precise and repeatable test conditions.

Versatility: Suitable for a wide range of products from electronics to automotive parts.

Data Integration: Advanced software allows real-time monitoring and data logging for detailed analysis.

For example, consumer electronics manufacturers can use these chambers to simulate rapid temperature changes and mechanical shocks that devices might face during shipping and daily use. This ensures products are robust and less prone to early failures.

How HALT HASS Testing Enhances Product Development

Incorporating HALT and HASS testing into your development cycle offers several strategic advantages:

Accelerated Learning: By pushing products beyond normal limits, teams gain insights into failure mechanisms quickly.

Design Optimization: Early identification of weak points allows for targeted improvements, reducing redesign cycles.

Risk Mitigation: Products that pass HALT are less likely to fail in the field, lowering warranty and liability risks.

Compliance and Certification: Many industries require rigorous environmental testing; HALT and HASS help meet these standards.

Competitive Advantage: Delivering reliable products faster strengthens market position.

For example, military equipment must operate reliably in extreme environments. HALT testing ensures components can survive rapid temperature shifts and intense vibrations encountered in the field. This reliability is critical for mission success and safety.

Implementing HALT and HASS Testing: Best Practices

To maximize the benefits of HALT and HASS testing, consider these best practices:

Define Clear Objectives: Understand what failure modes you want to detect and what product specifications must be met.

Use Realistic Stress Profiles: Base temperature and vibration levels on actual use conditions plus safety margins.

Integrate Testing Early: Incorporate HALT during the design phase to catch issues before production.

Train Personnel: Ensure engineers and technicians understand test procedures and data interpretation.

Leverage Data Analytics: Use software tools to analyze test results and identify trends.

Maintain Equipment: Regular calibration and maintenance of chambers ensure accurate and reliable testing.

By following these guidelines, you can improve product quality and reduce time to market effectively.

Incorporating HALT and HASS testing chambers into your product development and manufacturing processes is a strategic investment. These chambers provide a controlled environment to push products beyond their limits, uncover hidden weaknesses, and ensure consistent quality. Whether you are developing automotive components, aerospace systems, or consumer electronics, leveraging the advantages of HALT and HASS testing can lead to more reliable products, cost savings, and satisfied customers.

For those looking to enhance their testing capabilities, exploring advanced solutions like the halt hass chamber can be a game-changer. It combines efficiency, precision, and versatility to meet the demanding needs of modern product development.

By embracing these technologies and best practices, you position your products and company for success in competitive and challenging markets.