Differences between HALT and HASS testing profiles

- Oct 20, 2025

- 2 min read

HALT and HASS are two essential tools in a robust reliability program, but they serve very different purposes at different stages of a product's lifecycle. Understanding their differences ensures each test is used to maximum effect and helps deliver durable, high-quality products to market.

Purpose and Timing

HALT (Highly Accelerated Life Testing):

Used during the R&D and prototype phase.

Designed to intentionally push the product beyond its specifications, uncovering fundamental design and process weaknesses.

Not structured as a pass/fail test, but as a discovery tool for improving design robustness.

HASS (Highly Accelerated Stress Screening):

Employed in production, after the design has passed HALT.

Stress levels are aggressive but within known safe margins—these margins are determined from earlier HALT results.

Focuses on screening out manufacturing defects before delivery, protecting customers from early failures.

Stress Profiles and Test Outcomes

HALT:

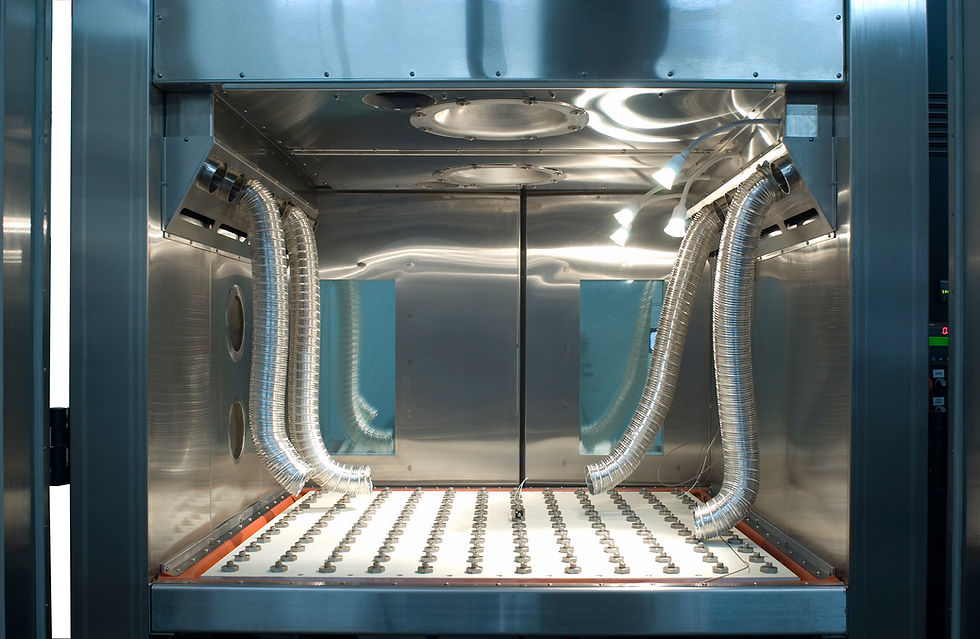

Applies rapidly increasing stresses—temperature extremes, vibration—until the product fails or is destroyed.

Documents all failure modes, operational limits, and destruct limits so engineers can redesign or reinforce those weak points.

Outcome: recommendations to improve product durability, define safe working and destruction limits.

HASS:

Applies the combined environmental stresses defined by HALT—but stops short of destruction, staying within limits that won't cause irreversible damage to good products.

Any unit that fails during HASS is removed or investigated for potential process issues, component drift, or other manufacturing faults.

Outcome: defective units are identified and filtered out, assuring reliable product delivery.

Process Overview

Feature | HALT | HASS |

Objective | Reveal design and process weaknesses | Screen out manufacturing defects |

When Used | R&D, prototyping, early design | Production, just before delivery |

Stress Levels | Beyond operational/destruction thresholds | Aggressive but below destructive thresholds |

Test Outcome | Insights for improvement, design margins | Pass/fail: units must survive or are rejected |

Frequency | Once or per major design iteration | Routinely for each production batch |

Typical Result | Design updates, improved robustness | High reliability, fewer out-of-box failures |

Complementary Role

HALT and HASS are not alternatives. HALT defines what the limits are and ensures a rugged design; HASS takes that information to optimize production screening. Used together, they form a closed-loop system that boosts both product robustness and manufacturing quality, minimizing failures both before and after launch.

By applying these two strategies serially, companies can revolutionize their product reliability results and consumer satisfaction.