Comprehensive Guide to Environmental Stress Testing

- Oct 16, 2025

- 4 min read

When developing products for demanding industries such as automotive, aerospace, and consumer electronics, ensuring durability is not just a goal - it is a necessity. Stress testing for durability plays a critical role in verifying that products can withstand the harsh conditions they will face during their lifecycle. In this guide, I will walk you through the essentials of stress testing, focusing on practical insights and actionable recommendations to help you design and execute effective tests.

Understanding Stress Testing for Durability

Stress testing for durability involves subjecting a product to conditions that simulate real-world environmental and mechanical stresses. The objective is to identify potential failure points before the product reaches the market. This process helps manufacturers improve product reliability, reduce warranty costs, and meet stringent industry standards.

Durability stress tests often include exposure to temperature extremes, humidity, vibration, shock, and other environmental factors. These tests are designed to accelerate aging and wear, revealing weaknesses that might not be apparent under normal use.

For example, in the automotive industry, components such as engine parts or electronic control units undergo vibration and thermal cycling tests to ensure they can endure years of operation. Similarly, aerospace components are tested for resistance to rapid temperature changes and mechanical shocks experienced during flight.

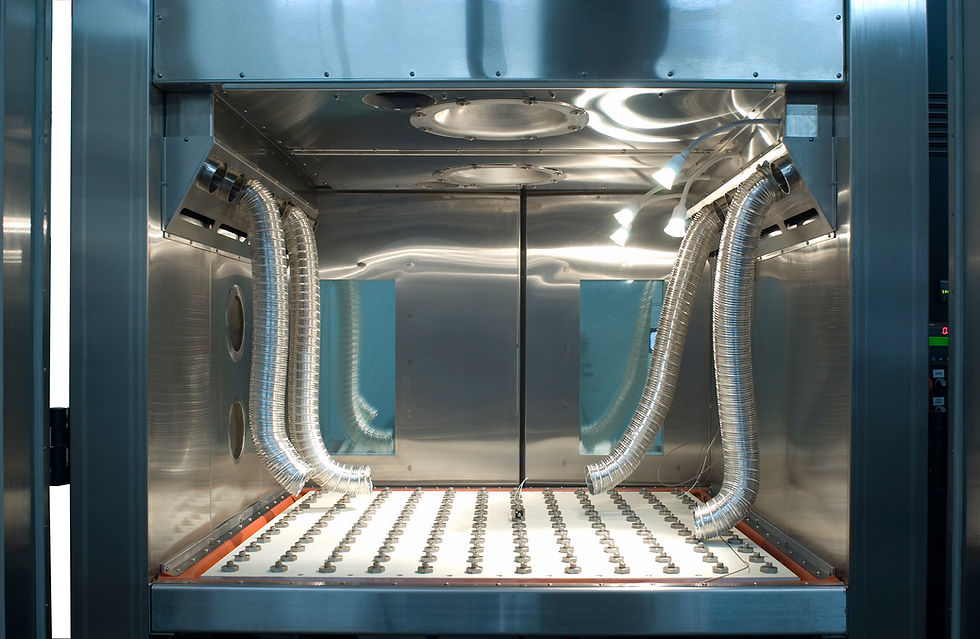

Caption: Vibration testing chamber simulating real-world mechanical stresses on automotive parts.

Key Methods in Stress Testing for Durability

There are several methods used to stress test products for durability. Selecting the right method depends on the product type, expected use conditions, and industry requirements. Here are some of the most common approaches:

Thermal Cycling

This method exposes the product to alternating high and low temperatures to simulate day-night cycles or seasonal changes. It helps identify issues like material fatigue, solder joint failures, and seal degradation.

Vibration Testing

Products are subjected to controlled vibrations that mimic transportation, operation, or environmental vibrations. This test is crucial for electronic devices, automotive parts, and aerospace components.

Humidity Testing

High humidity environments can cause corrosion, mold growth, and electrical failures. Humidity chambers maintain controlled moisture levels to evaluate product resistance.

Shock Testing

Sudden impacts or drops are simulated to assess the product’s ability to withstand accidental shocks during handling or operation.

Combined Environmental Testing

Often, products face multiple stresses simultaneously. Combined testing chambers allow simultaneous exposure to temperature, humidity, and vibration, providing a more realistic durability assessment.

When designing a test plan, it is essential to define the stress levels, duration, and cycles based on the product’s expected environment. Overly aggressive testing can cause unrealistic failures, while insufficient stress may miss critical weaknesses.

Caption: Combined environmental test chamber used for simultaneous temperature and humidity stress testing.

What are Examples of Environmental Stress?

Environmental stress refers to external conditions that can negatively impact a product’s performance and lifespan. Understanding these stresses helps in designing relevant tests. Here are some typical examples:

Temperature Extremes: Exposure to very high or low temperatures can cause expansion, contraction, and material degradation.

Humidity and Moisture: Moisture ingress can lead to corrosion, short circuits, and mold.

Vibration and Shock: Mechanical forces from transportation, operation, or accidental drops can cause structural damage.

UV Radiation: Prolonged exposure to sunlight can degrade plastics, coatings, and adhesives.

Salt Spray and Corrosive Atmospheres: Common in marine or industrial environments, these stresses accelerate corrosion.

Dust and Particulate Matter: Dust ingress can impair mechanical parts and electronics.

For instance, consumer electronics often undergo temperature and humidity cycling to ensure they function reliably in different climates. Military equipment may be tested for salt spray and shock resistance to meet battlefield conditions.

Understanding the specific environmental stresses your product will face allows you to tailor your testing protocols effectively.

Caption: Salt spray chamber used to simulate corrosive environments for metal components.

Designing an Effective Stress Testing Program

Creating a robust stress testing program requires careful planning and execution. Here are some practical steps to guide you:

Define Objectives Clearly

Identify what you want to achieve with the test. Are you validating design robustness, identifying failure modes, or verifying compliance with standards?

Select Relevant Stress Factors

Choose environmental and mechanical stresses that reflect real-world conditions your product will encounter.

Set Test Parameters

Determine stress levels, duration, and cycles. Use industry standards or historical data as references.

Use Proper Equipment

Invest in reliable environmental chambers and vibration systems. Advanced equipment allows precise control and repeatability.

Monitor and Record Data

Use sensors and data acquisition systems to track product behavior during tests. This data is invaluable for failure analysis.

Analyze Failures Thoroughly

When failures occur, perform root cause analysis to understand mechanisms and improve design.

Iterate and Improve

Use test results to refine product design and repeat testing as necessary.

By following these steps, you can develop a testing program that not only identifies weaknesses but also accelerates product development cycles.

Leveraging Advanced Testing Solutions

To meet the increasing demands of modern industries, advanced testing solutions are essential. Companies like Hanse Environmental provide state-of-the-art environmental testing chambers and vibration systems designed to simulate complex stress scenarios accurately.

These systems offer features such as:

Precise temperature and humidity control

Multi-axis vibration capabilities

Programmable test sequences

Real-time data monitoring and logging

Compliance with international testing standards

Using such equipment enables you to conduct comprehensive tests that closely mimic actual operating environments. This approach reduces the risk of unexpected failures in the field and supports faster time-to-market.

If you want to explore more about how to implement effective environmental stress testing in your workflow, I recommend checking out specialized providers who can tailor solutions to your specific needs.

Stress testing for durability is a cornerstone of product reliability. By understanding the types of stresses, selecting appropriate test methods, and leveraging advanced equipment, you can ensure your products meet the highest standards. This proactive approach not only safeguards your brand reputation but also drives innovation and efficiency in product development.