HALT and HASS Testing Methods: Key Differences

- Jan 15

- 4 min read

When developing products for demanding industries such as automotive, aerospace, and electronics, ensuring reliability is paramount. Two testing methods often come up in this context: HALT (Highly Accelerated Life Testing) and HASS (Highly Accelerated Stress Screening). While they share similarities, their purposes, applications, and execution differ significantly. Understanding these differences can help you select the right approach to improve product durability and reduce failure rates.

Understanding HALT and HASS Testing Methods

HALT and HASS are both accelerated testing techniques designed to expose products to extreme conditions. However, their goals and implementation vary.

HALT is primarily a development tool. It aims to identify design weaknesses early by pushing a product beyond its specified limits. This process helps engineers discover failure modes and improve the design before mass production.

HASS, on the other hand, is a production screening method. It focuses on detecting manufacturing defects and process variations that could cause early-life failures. HASS is applied to every unit or batch during production to ensure consistent quality.

Both methods use environmental stressors such as temperature cycling, vibration, and humidity, but the intensity and duration differ. HALT tests are more aggressive and exploratory, while HASS tests are controlled and repeatable.

Key Differences at a Glance

| Aspect | HALT | HASS |

|----------------------|----------------------------------|----------------------------------|

| Purpose | Design improvement | Production screening |

| Test Intensity | Extreme, beyond product limits | Moderate, within product limits |

| Application Stage | Early development | Manufacturing and production |

| Test Duration | Short, exploratory | Longer, repeatable |

| Failure Detection | Design weaknesses | Manufacturing defects |

Understanding these distinctions helps in applying the right method at the right stage of product development and manufacturing.

How HALT and HASS Testing Methods Complement Each Other

In practice, HALT and HASS are complementary. HALT is used during the design phase to push the product to its limits and identify potential failure points. Engineers use the data to refine the design, improve materials, and enhance assembly processes.

Once the design is finalized and production begins, HASS takes over. It acts as a quality gate, screening each product or batch to catch defects introduced during manufacturing. This screening helps reduce warranty costs and field failures.

For example, in the automotive industry, HALT might reveal that a certain electronic component fails under rapid temperature cycling. The design team can then select a more robust component or improve thermal management. Later, during production, HASS ensures that every unit meets the improved design standards by subjecting them to controlled stress tests.

This synergy between HALT and HASS accelerates development cycles and improves product reliability, aligning with the goals of companies like Hanse Environmental, which provide advanced environmental testing chambers and vibration systems.

What is HASS used for?

HASS is primarily used to detect latent defects that could cause early failures in the field. These defects often arise from manufacturing inconsistencies such as solder joint issues, component misalignment, or assembly errors.

By applying controlled stress conditions—such as temperature cycling combined with vibration—HASS forces weak units to fail before they reach customers. This process reduces the risk of costly recalls and enhances brand reputation.

In industries like aerospace and military, where product failure can have severe consequences, HASS is critical. It ensures that every product leaving the production line meets stringent reliability standards.

Moreover, HASS testing can be customized based on the product and manufacturing process. For instance, vibration profiles can be tailored to simulate real-world conditions specific to automotive or consumer electronics applications.

Practical Recommendations for Implementing HALT and HASS

Implementing HALT and HASS effectively requires careful planning and execution. Here are some actionable recommendations:

Start with HALT early in the design phase. Use it to identify design weaknesses and improve product robustness before tooling and production begin.

Develop detailed test plans. Define stress levels, durations, and failure criteria based on product specifications and industry standards.

Use reliable test equipment. Invest in advanced environmental chambers and vibration systems that can simulate the required stress profiles accurately.

Train your team. Ensure engineers and technicians understand the objectives and procedures of both HALT and HASS.

Integrate HASS into production lines. Automate testing where possible to maintain throughput without compromising quality.

Analyze failure data thoroughly. Use insights from HALT and HASS to continuously improve design and manufacturing processes.

Document all test results. Maintain traceability and support compliance with industry regulations.

By following these steps, manufacturers can reduce time-to-market, lower warranty costs, and enhance product reliability.

Choosing the Right Environmental Testing Chamber

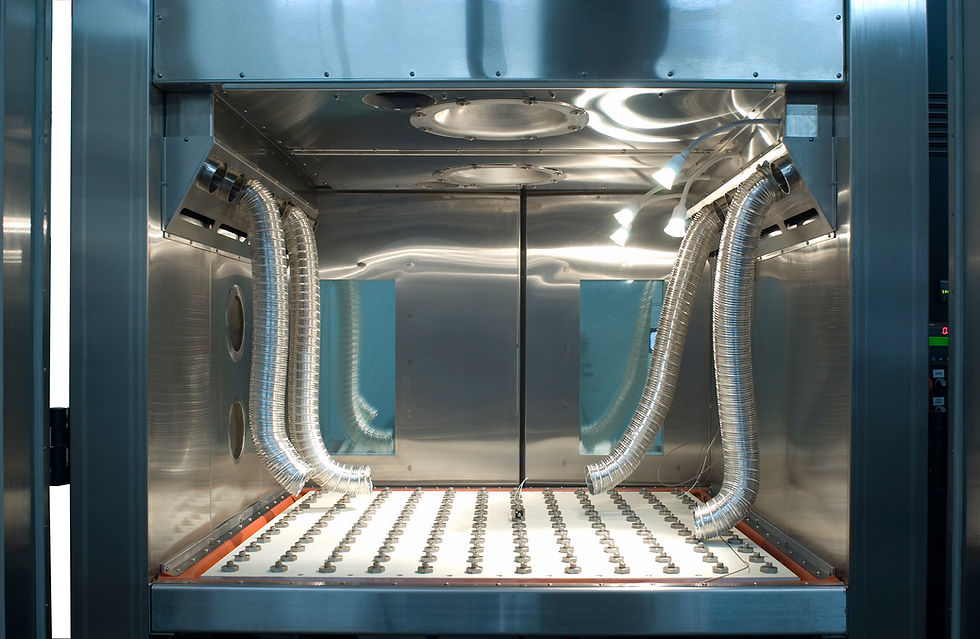

Selecting the appropriate environmental testing chamber is crucial for successful HALT and HASS implementation. Chambers must support rapid temperature changes, precise humidity control, and vibration capabilities.

For example, a hass chamber designed for production screening should offer repeatable stress profiles and easy integration with automated test systems. Meanwhile, HALT chambers require flexibility to push products beyond their limits safely.

Consider factors such as chamber size, control accuracy, and compatibility with your product types. Partnering with a provider like Hanse Environmental ensures access to cutting-edge technology tailored to your testing needs.

Enhancing Product Reliability Through Accelerated Testing

Incorporating HALT and HASS into your product development and manufacturing processes is a strategic investment. These methods help uncover hidden weaknesses, improve design robustness, and ensure consistent quality.

By understanding the key differences and applications of HALT and HASS, you can optimize your testing strategy. This approach not only accelerates development cycles but also builds confidence in your products' performance under real-world conditions.

Ultimately, leveraging advanced environmental testing chambers and vibration systems enables you to meet demanding industry standards and deliver reliable products that stand the test of time.