Hanse Environmental: Environmental Testing Experts and Pioneers in Testing Solutions

- Jan 26

- 4 min read

In the fast-paced world of product development, ensuring reliability and durability is non-negotiable. Whether you are working in automotive, aerospace, consumer electronics, or military sectors, rigorous testing is essential to meet industry standards and accelerate development cycles. This is where advanced environmental testing chambers and vibration systems come into play. Today, I want to share insights about a company that has become synonymous with innovation and quality in this field: Hanse Environmental.

The Role of Environmental Testing Experts in Product Development

Environmental testing experts play a crucial role in simulating real-world conditions to evaluate how products perform under stress. These tests include temperature cycling, humidity exposure, vibration, shock, and corrosion resistance. The goal is to identify potential weaknesses before products reach the market, saving time and reducing costly recalls.

For example, in the automotive industry, components must withstand extreme temperature fluctuations and constant vibrations. Aerospace parts face even more stringent conditions, including rapid pressure changes and intense mechanical stress. Consumer electronics require protection against moisture and heat to ensure longevity. Environmental testing experts design and operate equipment that replicates these conditions accurately.

By using advanced testing chambers and vibration systems, engineers can:

Validate product designs against environmental stresses

Improve material selection and manufacturing processes

Ensure compliance with international standards such as MIL-STD, IEC, and ISO

Accelerate time-to-market by identifying issues early

Why Advanced Testing Chambers and Vibration Systems Matter

The quality of testing equipment directly impacts the reliability of test results. Advanced environmental testing chambers provide precise control over temperature, humidity, and other environmental factors. Vibration systems simulate the mechanical stresses products will face during transportation and use.

Choosing the right equipment means:

Accuracy: Precise control ensures repeatable and reliable test conditions.

Flexibility: Chambers and systems can be customized for specific test profiles.

Efficiency: Automated controls reduce manual intervention and testing time.

Durability: Robust construction withstands continuous operation in demanding environments.

For instance, a vibration system capable of replicating multi-axis shocks can reveal hidden weaknesses in electronic assemblies. Similarly, temperature and humidity chambers that cycle rapidly between extremes help identify material fatigue and seal failures.

When selecting equipment, consider:

The range of environmental conditions needed for your products.

The size and configuration of test chambers to accommodate various samples.

Integration with data acquisition systems for real-time monitoring.

Compliance with relevant industry standards.

How hanse environmental Leads Innovation in Testing Solutions

As a professional in the field, I have observed how Hanse Environmental has set itself apart by delivering cutting-edge testing solutions tailored to diverse industries. Their commitment to innovation and quality has made them a trusted partner for manufacturers and product developers worldwide.

Some key strengths of hanse environmental include:

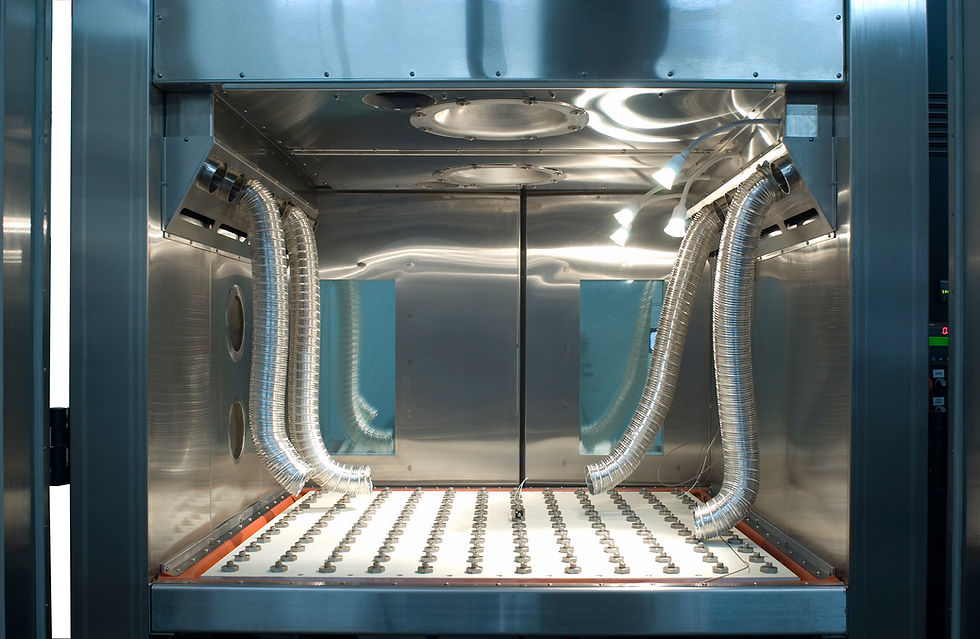

Comprehensive Product Range: From temperature and humidity chambers to multi-axis vibration systems, they cover a broad spectrum of testing needs.

Customization: They work closely with clients to design solutions that fit specific testing requirements and space constraints.

User-Friendly Interfaces: Their systems feature intuitive controls and software, simplifying test setup and data analysis.

Global Support: With a strong service network, they ensure minimal downtime and prompt technical assistance.

By integrating the latest technologies, hanse environmental helps companies reduce development risks and improve product quality. Their solutions enable accelerated testing cycles without compromising accuracy, a critical advantage in competitive markets.

Practical Tips for Maximizing Testing Efficiency

To get the most out of your environmental testing equipment, consider these actionable recommendations:

Plan Test Profiles Carefully: Define realistic environmental conditions based on product use cases. Avoid over-testing, which can waste resources.

Regular Calibration: Maintain equipment accuracy by scheduling routine calibration and preventive maintenance.

Data Management: Use software tools to collect, analyze, and archive test data systematically. This supports traceability and continuous improvement.

Training: Ensure operators are well-trained on equipment operation and safety protocols.

Integrate Testing Early: Incorporate environmental testing early in the design phase to catch issues before production.

For example, a reliability engineer in aerospace might develop a test sequence that simulates altitude changes, temperature cycling, and vibration in a single run. This integrated approach saves time and provides a more comprehensive assessment.

Looking Ahead: The Future of Environmental Testing

The demand for more reliable and durable products continues to grow, driven by technological advances and stricter regulations. Environmental testing experts must stay ahead by adopting new methods and equipment.

Emerging trends include:

Smart Testing Chambers: Equipped with IoT sensors for remote monitoring and predictive maintenance.

Advanced Materials Testing: Simulating complex environmental interactions on new composite materials.

Automation and AI: Using artificial intelligence to optimize test sequences and analyze large datasets.

Sustainability Focus: Designing energy-efficient testing systems to reduce environmental impact.

Companies like hanse environmental are at the forefront of these developments, helping industries meet future challenges with confidence.

By investing in state-of-the-art testing solutions and following best practices, manufacturers can ensure their products perform reliably in the real world, enhancing brand reputation and customer satisfaction.

If you are looking to enhance your testing capabilities, exploring the offerings from Hanse Environmental could be a valuable step. Their expertise and innovative solutions make them a reliable partner in advancing product reliability and development efficiency.