Hanse Environmental: Environmental Testing Experts Pioneering Testing Solutions

- 5 days ago

- 4 min read

In the fast-paced world of product development, ensuring reliability and durability is non-negotiable. Whether you are working on automotive components, aerospace systems, or consumer electronics, rigorous testing is essential to meet industry standards and accelerate development cycles. This is where advanced environmental testing chambers and vibration systems come into play. Among the leaders in this field, hanse environmental stands out as a pioneer, offering innovative solutions that help manufacturers push their products to the limits and beyond.

The Role of Environmental Testing Experts in Product Development

Environmental testing experts play a crucial role in validating product performance under various conditions. These professionals design and implement tests that simulate real-world environments such as temperature extremes, humidity, vibration, and shock. The goal is to identify potential weaknesses before products reach the market, reducing costly recalls and enhancing customer satisfaction.

For example, in the automotive industry, components must withstand temperature fluctuations from freezing winters to scorching summers. Environmental testing chambers replicate these conditions, allowing engineers to observe how materials and electronics behave. Similarly, aerospace components face intense vibration and pressure changes during flight, which vibration systems can simulate accurately.

By integrating these testing methods early in the development process, companies can:

Detect design flaws and material failures

Improve product durability and safety

Comply with regulatory standards

Shorten time-to-market through accelerated testing cycles

Advanced Testing Solutions for Diverse Industries

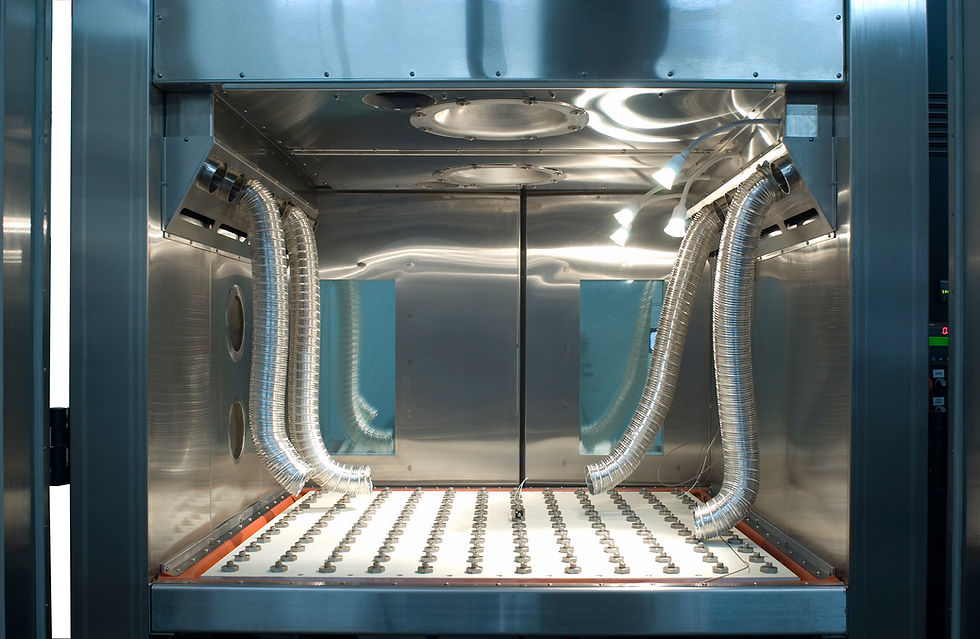

The diversity of industries relying on environmental testing demands versatile and precise equipment. Hanse Environmental has developed a range of chambers and vibration systems tailored to meet these varied needs. Their solutions cover:

Temperature and Humidity Chambers: These simulate climatic conditions from -70°C to +180°C with controlled humidity levels. This range is critical for testing electronics, automotive parts, and aerospace components.

Vibration Test Systems: Designed to replicate mechanical stresses during transportation or operation, these systems help identify structural weaknesses.

Combined Environmental Testing: Some products require simultaneous exposure to temperature, humidity, and vibration. Hanse Environmental’s integrated systems allow for such complex testing scenarios.

For instance, consumer electronics manufacturers can use these chambers to test smartphones for resistance to heat and moisture, while military equipment developers can simulate harsh battlefield conditions to ensure reliability.

The flexibility and precision of these systems enable engineers to customize test profiles according to specific product requirements, ensuring relevant and actionable results.

Key Features That Set Hanse Environmental Apart

What makes Hanse Environmental a trusted name among environmental testing experts? Several features distinguish their products:

High Precision Control: Their chambers maintain exact temperature and humidity levels with minimal fluctuation, ensuring consistent test conditions.

Robust Construction: Built to withstand continuous operation, these systems offer long-term reliability and low maintenance.

User-Friendly Interfaces: Intuitive software allows technicians to program complex test cycles easily and monitor progress in real time.

Customizable Solutions: Hanse Environmental works closely with clients to tailor equipment specifications, accommodating unique testing needs.

Compliance with Standards: Their products meet international testing standards such as IEC, MIL-STD, and ISO, ensuring test validity and acceptance.

These features translate into practical benefits for manufacturers and product developers. For example, precise control reduces the risk of false test results, while customizable solutions mean no compromise on testing scope. The user-friendly interface saves time and reduces errors during test setup.

Practical Recommendations for Maximizing Testing Efficiency

To get the most out of environmental testing chambers and vibration systems, consider the following best practices:

Define Clear Test Objectives: Understand what you want to achieve with each test. Are you validating durability, safety, or compliance? Clear goals help in selecting the right test parameters.

Simulate Realistic Conditions: Use data from actual operating environments to create test profiles. This increases the relevance of test results.

Schedule Regular Calibration: Maintain equipment accuracy by calibrating sensors and controls periodically.

Document Test Procedures: Keep detailed records of test setups, conditions, and outcomes. This supports traceability and continuous improvement.

Leverage Automation: Use software features to automate repetitive tests, freeing up technician time for analysis and troubleshooting.

By following these recommendations, you can enhance the reliability of your testing process and gain deeper insights into product performance.

Looking Ahead: The Future of Environmental Testing

The demand for more robust and reliable products continues to grow, driven by technological advancements and stricter regulations. Environmental testing experts must evolve alongside these trends. Innovations such as:

IoT-Enabled Testing Chambers: Allowing remote monitoring and data collection for improved test management.

AI-Driven Analysis: Using machine learning to predict failure modes and optimize test cycles.

Sustainable Testing Practices: Reducing energy consumption and environmental impact of testing equipment.

Hanse Environmental is actively investing in these areas to maintain its position as a leader in testing solutions. Their commitment to innovation ensures that manufacturers can rely on cutting-edge technology to meet future challenges.

Incorporating these advancements into your testing strategy will not only improve product quality but also enhance operational efficiency.

Enhancing Product Reliability with Hanse Environmental

Choosing the right partner for environmental testing equipment is critical. With a proven track record and a comprehensive product portfolio, hanse environmental offers the tools and expertise needed to rigorously test and improve products across industries. Their advanced chambers and vibration systems empower engineers to push boundaries, ensuring products perform reliably under the most demanding conditions.

By integrating these solutions into your development process, you can accelerate innovation, reduce risk, and deliver superior products to market faster. The future of product reliability starts with precise, comprehensive testing - and Hanse Environmental is ready to help you get there.