Maximizing Product Reliability with HALT Chamber Systems

- 3 days ago

- 4 min read

In today’s competitive market, ensuring product reliability is not just a goal but a necessity. Products must withstand harsh environments and rigorous use without failure. This is where HALT chamber systems come into play. These advanced testing tools help manufacturers identify weaknesses early in the development process, saving time and resources while improving product durability. In this post, I will share insights on how to maximize product reliability using HALT chamber systems, drawing from practical experience and industry best practices.

Understanding HALT Chamber Systems and Their Role in Reliability Testing

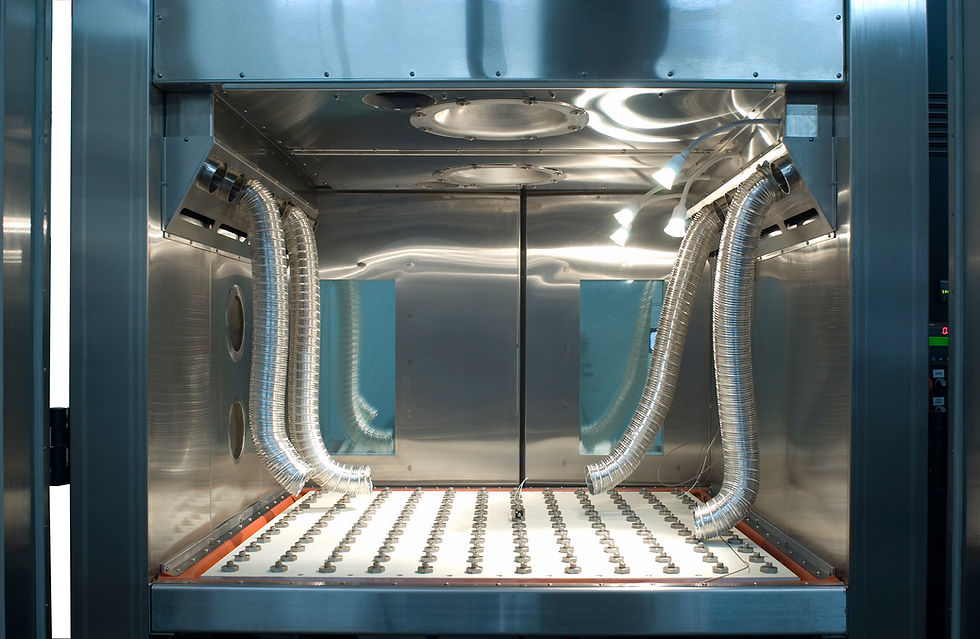

HALT stands for Highly Accelerated Life Testing. It is a method designed to push products beyond their normal operating limits to uncover potential failure modes quickly. HALT chamber systems combine environmental stressors such as temperature extremes, rapid thermal cycling, and vibration to simulate real-world conditions in a compressed timeframe.

These chambers allow engineers to:

Detect design weaknesses early

Improve product robustness

Reduce warranty costs

Accelerate product development cycles

For example, an automotive electronics manufacturer might use a HALT chamber system to expose a control module to rapid temperature changes from -40°C to +125°C while simultaneously applying vibration. This helps reveal solder joint failures or component weaknesses that might only appear after years of use in the field.

By integrating HALT testing into your development process, you can identify and fix issues before mass production, ensuring higher reliability and customer satisfaction.

Key Features of HALT Chamber Systems That Enhance Testing Efficiency

When selecting or using a HALT chamber system, certain features significantly impact the effectiveness of your testing:

Wide Temperature Range

The ability to cycle through extreme temperatures quickly is essential. Look for systems that can reach temperatures as low as -100°C and as high as +200°C or more.

Rapid Thermal Ramp Rates

Fast temperature changes (up to 70°C per minute) help accelerate the discovery of thermal-related failures.

Integrated Vibration System

Combining vibration with thermal stress simulates real-world mechanical and environmental conditions.

User-Friendly Control Software

Intuitive interfaces and programmable test profiles save time and reduce operator error.

Data Acquisition and Analysis Tools

Real-time monitoring and detailed reporting help engineers pinpoint failure causes.

For instance, aerospace component developers benefit from HALT chamber systems that can simulate the rapid temperature fluctuations and vibrations experienced during flight. This ensures components meet stringent reliability standards before deployment.

What is the difference between HASS and HALT?

Understanding the distinction between HALT and HASS is crucial for applying the right testing strategy.

HALT (Highly Accelerated Life Testing) is an early-stage testing method. It pushes products beyond their design limits to identify weaknesses and failure modes quickly. The goal is to improve the design by exposing vulnerabilities.

HASS (Highly Accelerated Stress Screening) is a production-level screening process. It applies stresses slightly above normal operating conditions to detect manufacturing defects or process variations. HASS ensures that only robust products reach customers.

In practice, HALT is used during product development, while HASS is implemented during manufacturing. Both are complementary and essential for maximizing product reliability.

By integrating both HALT and HASS into your quality assurance workflow, you can catch design flaws early and maintain consistent product quality during production.

Practical Tips for Maximizing Reliability Using HALT Chamber Systems

To get the most out of your HALT chamber system, consider these actionable recommendations:

Define Clear Test Objectives

Know what failure modes you want to uncover. Tailor your test profiles accordingly.

Use Realistic Test Samples

Test fully assembled products or representative prototypes to get accurate results.

Combine Stressors Thoughtfully

Apply temperature, vibration, and humidity in combinations that mimic actual use conditions.

Monitor Continuously

Use sensors and data logging to track product responses and identify failure points.

Iterate and Improve

Use HALT results to refine your design, then retest to verify improvements.

Train Your Team

Ensure operators understand the system and testing protocols to avoid errors.

For example, a consumer electronics company might discover that a particular solder joint fails under rapid thermal cycling combined with vibration. By redesigning the joint and retesting, they can significantly improve product lifespan.

Leveraging HALT Chamber Systems to Accelerate Product Development

One of the most valuable benefits of HALT chamber systems is their ability to shorten development cycles. Traditional reliability testing can take months or years, but HALT compresses this timeline by applying extreme stresses rapidly.

This acceleration allows teams to:

Identify and fix design flaws early

Reduce the number of physical prototypes needed

Make informed decisions faster

Bring products to market more quickly

For instance, in the aerospace industry, where certification and reliability are critical, HALT testing can reduce the time needed to validate components, helping companies meet tight project deadlines without compromising quality.

By integrating HALT testing early and often, you create a feedback loop that continuously improves product robustness and speeds up time-to-market.

Final Thoughts on Enhancing Product Reliability with HALT Chamber Systems

Incorporating advanced environmental testing tools like HALT chamber systems is a strategic move for any manufacturer aiming to deliver reliable, high-quality products. These systems provide invaluable insights into product weaknesses, enabling targeted improvements that save time and costs.

Remember, the key to success lies in understanding the capabilities of your HALT chamber system, applying rigorous testing protocols, and using the data to drive design enhancements. Whether you are developing automotive electronics, aerospace components, or consumer devices, HALT testing is a powerful ally in your reliability engineering toolkit.

For those interested in exploring further, I recommend checking out the halt hass chamber solutions offered by Hanse Environmental. Their advanced chambers and vibration systems are designed to meet the demanding needs of modern product development and testing.

By embracing these technologies and best practices, you can confidently deliver products that stand up to the challenges of real-world use and exceed customer expectations.